Viagra gibt es mittlerweile nicht nur als Original, sondern auch in Form von Generika. Diese enthalten denselben Wirkstoff Sildenafil. Patienten suchen deshalb nach viagra generika schweiz, um ein günstigeres Präparat zu finden. Unterschiede bestehen oft nur in Verpackung und Preis.

Teknol.eu

P h a r m a c e u t i c a l t e c h n o l o g y

GMP SIzE REDucTION SYSTEMS

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

From millimetre to nanometre –

our service range

From milligram to tonne:

We develop versatile and efficient processing

innovative and sPecialised solutions

solutions for the size reduction/micronising of

For us, innovative technologies are state of the art. Our Pharma Division

pharmaceutical products. With many years of

leads the international market for powder processing equipment. We

experience, our team of engineers can offer

provide the entire range of size reduction technology, from deglomeration

you tried-and-tested, versatile concepts and

in the millimetre range right through to micronisation and nano-scale

standard solutions as well as special solutions

milling in the µm and nm range. We cater to R&D gram-scale requirements

tailored to your specific requirements.

as well as to production batches that weigh several tonnes.

our customers process the following

r&d – when every gram counts

products (examples):

The course of future production methods is set as early as the R&D

- Pharmaceutical substances of category

stage. Research laboratories need to work with technologies that are

OEB 1 - OEB 6 with resultant OEL values of

also available for later production processes. At this early stage, it is

between < 50 mg/m3 and < 200 ng/m3

important that research labs have the right equipment at their disposal.

- Excipients such as lactose, sugar, cellulose

We offer very small systems such as the Picoline machines for processing

- DPI (carriers and active substances)

gram-scale batches. They are based on well-established production lines

and provide customers with a high level of reliability, ensuring that the

- Nanopharmaceuticals

production method can easily be applied to the required production scale

- Hot-melt-extruded pharma polymers

at a later date.

multi-mill systems

Multi-processing systems are a speciality of the Pharma Division. These

systems comprise different mill types which share the same ancillary

equipment. These systems are not only extremely versatile, but they also

reduce capital expenditure and validation requirements to a minimum.

aPPlication areas oF diFFerent mill tyPes

Wet agitated media mill AHM

Spiral jet mill AS

Fluidised bed opposed jet mill AFG

classifier mills zPS/AcM

Fine impact mills uPz

ciP / siP

cleaning In Place and Sterilisation In Place are highly exacting processes

which place stringent requirements on system design and engineering.

Our Pharmaplex® bearing assembly allows sterilisation with saturated

steam for high-speed, oil-free bearing concepts used in mills and metering

equipment.

containment

Increasingly exacting occupational safety requirements and the use

Passion For Pharma

of highly active pharmaceutical substances compel manufacturers

to reassess their system components. The integration of grinding

- Our systems comply with the most exacting

technology into isolators proved to be highly challenging and

international standards:

often turned out to be too complex for isolator manufacturers. As

- Product- and process-contact parts are made of

the responsibility for the complete system should lie with only one

AISI 316L stainless steel

single supplier, Hosokawa Alpine has been developing integrated

- Surface roughness standard Ra < 0.8 µm

containment milling systems for fifteen years. The benefits are obvious:

(depending on the project Ra < 0.4 µm or

our customers are supplied with complete solutions from one source

Ra < 0.25 µm with/without electropolishing)

that do not pose any integration problems.

- Seal and filter material suitable for use with

food and drugs according to FDA 21cFR177.2600

- Particle- and oil-free, clear separation between

Process safety and repeatability is ensured by monitoring and

drive and process thanks to pharmaceutical

controlling all relevant parameters. We also integrate in-line laser

diffraction systems made by different manufacturers into our systems.

- Encapsulated, permanently lubricated bearings

These allow monitoring and inspection of particle sizes.

or use of uSDA-H1 lubricant

- Fully cIP/SIP compatible machines thanks to

test and rental equiPment

patented Pharmaplex® bearing concept

Our state-of-the-art test centre equipment is available for customer

- Mostly monobloc components with a low

tests. However, many pharmaceutical chemicals are highly toxic and

number of welding seams and seals

cannot be sent to us for safety- or customs-related reasons. In these

- Design free of dead spots

cases, we offer our customers a wide range of rental equipment which

- Drainage and evacuation points for residual air

allow tests on the customer's site.

removal in cIP/SIP-compatible systems

- control according to GAMP 4/5 and 21 cFR Part

Wet-grinding at its finest

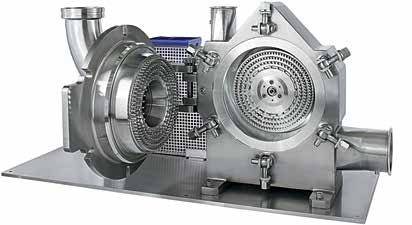

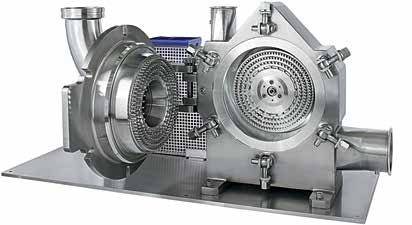

uPZ fine impact mills

Some like it coarse

acm/ZPs classifier mills

The dose makes the medicine

spiral jet mills

More than just accessories

Fluidised bed opposed jet mills

ultrafine and sharp top cut

Trust but verify

validation

unbeatable versatility

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

Fine imPact mills

and Particle

uPZ – coarse to Fine

areas oF aPPlication

Metformin HCL - UPZ (Pin Disc)

Fine impact mills or universal mills are used for fine and ultrafine

grinding. Depending on the product, these mills cover a fineness range

of between appr. 30 µm and 1,500 µm. As this mill type can be used

with different grinding elements, it is very versatile. Thanks to the rotor's

ventilation effect, the product is conveyed and cooled at the same time.

The end products are low in fines and have good flow properties.

- Typical area of application: deglomeration/

milling for end-product fineness of between 30 µm and 1,500 µm

- Grinding of soft to medium-hard materials

- Highly versatile thanks to different

grinding elements

- cooling effect thanks to high air flow

- End products are low in fines

315 UPZ fine impact mill

Pharma range

PrinciPle oF oPeration

uPz mechanical impact mills are be employed, e.g. a pin disc or

designed for dry grinding soft to a plate beater unit with profiled

medium-hard materials. The feed grinding track or a sieve grate.

material is charged to the centre of

The fineness is set by adjusting

the rotor equipped with grinding the rotor speed and the feed rate.

Pz fine impact millu

Max. air flow rate* (m³/h)

elements and is comminuted

by impact against the rotor and stator elements. After passing

through the grinding zone, the

product enters the mill housing and is then discharged from the

mill by gravitational force. The

rotation generates an air flow from which the end product is

* Max. values, depending on grinding tools** Max. speed, depending on grinding tools

extracted and charged to a filter.

For R&D application

Different grinding elements can

Practical examPles

End-product

fineness

put kg/h size

Acetylsalicylic acid

Acetylsalicylic acid

Powder fineness in % < µm – measuring points of particle size distribution

All values are non-binding reference values only

- Pin discs – for very high end-product

the versatile uPZ

fineness or for homogenisation

- Plate beater unit – cooling effect thanks to

sterile milling system incl.

- Plate beater unit with sieve ring – particle

feeding screw PDD 35 in

CIP/SIP-able design

size limitation with low fines content

- Plate beater unit with grinding track –

comminution of hard material

- combination of grinding track and sieve for

better particle size control

- Grinding tracks available in different

geometries for optimsation

100 UPZ

cryogenic milling system

with Alpine KF 40

screw cooler

100 UPZ

isolator solution with integrated

in-line particle analysis

and PDD 25 screw feeder

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

mikro acm + ZirkoPlex ZPs –

sharP toP cut

areas oF aPPlication

classifier mills are used for the ultrafine grinding of soft material with

an end-product fineness of appr. < 10 - 150 µm. They offer a range of

advantages over fine impact mills. The integrated air classifier gua-

rantees end products that are free of oversized particles with a steep particle size distribution and sharp top cut control. Grinding and se-

classifier mill vs. fine impact mill

paration parameters can be set independently for optimum results,

which ensures reliable product quality for the different particle sizes

or product properties required. The high air/gas flow cools the product.

distinction between acm + ZPs

During its corporate history, Hosokawa Alpine has developed two

different types of classifier mills, and both have become established

in their own right and have found their optimum area of application.

The Mikro AcM with its straightforward design is used all over the world in practically all industries, also in the pharmaceuticals segment.

- Typical area of application in the

pharmaceuticals industry is for particle sizes of between 10 µm and 150 µm

- Guaranteed top cut control thanks to

integrated air classifier

- Steep particle size distribution

- Optimum setting of grinding parameters

- cool grinding thanks to high air/gas flow

Pressure shock resistant

Maschine for Integration

Execution Easy Clan

in Cleanroom wall

Like the AcM, the pharma product chamber often allows execution of the AcM is a twin-

the comminution of sticky and

rotor classifier mill with a compact adhesive product. The classifier footprint that can be opened from

head of the zPS is identical

the top for easy access, inspection to that of Hosokawa Alpine's and cleaning. Thanks to its lean classifiers of the ATP range design, the AcM is inexpensive and is also used in simple air and cost-efficient in maintenance. classifiers or in combination The increased air flow allows with AFG fluidised bed opposed easy processing of heat-sensitive jet mills. This approach allows

70 ZPS isolator solution with PDD 25

metering screw

materials. In the pharmaceuticals the use of the zPS in so-called industry, the AcM is typically used multi-process systems. In this for the production of excipients set-up, the ATP classifier head and carrier materials, often in is the central component and mono-product systems with the grinding units for zPS, AFG continuous production or for large and ATP can be interchanged batch sizes.

very easily. The bearings for zPS the machine sizes from 50 zPS classifiers and mills are tried-

through to 200 zPS are popular

The zPS with its horizontal and-tested air-purged systems for very small API batches – also classifying wheel offers sharp top

which are available in a cIP/

for high active pharmaceuticals

cut control even when processing

SIP-compatible design. used by in contained installations.

challenging materials. The larger the pharmaceuticals industry,

Throughput

End-product fineness

Machine size

Powder fineness in % < µm – measuring points of particle size distribution

All values are non-binding reference values on

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

For R&D application

mikro acm + ZirkoPlex ZPs –

sharP classiFier cut Point

Pharma range ZPs

PrinciPle oF oPeration

The zPS and the AcM are mechanical impact mills with an integrated

classifier designed for the dry fine grinding of soft to medium-hard

materials with a steep particle size distribution. comminution is performed by a high-speed rotating disc with grinding elements. The feed material is charged to the grinding chamber and is accelerated by

zPS classifier mill

ø grinding disc (m

Max. air flow rate

means of the grinding rotor. comminution is the result of the particles impacting against the grinding elements of the rotor and against

the grinding track. The grinding air flows through the grinding gap

between the rotor and grinding track from below, passes through a deflector vane ring and then flows through the classifying wheel located

in the mill head. The classifying effect of the classifying wheel means that fine particles are able to exit the mill entrained in the air and are

collected in a filter. coarse particles fall back onto the rotor and are comminuted further until the desired fineness is reached. The fineness

is set by adjusting the speeds of the grinding rotor and the classifying wheel as well as the air flow rate.

Pharma range acm

M classifier mill cA

Power classifier (kW)

Max. air flow rate

the versatile acm

200 ZPS detail

40 ACM classifier wheel

ACM 2 EC

in special Pharma design

the versatile ZPs

100 ZPS detail

70 ZPS Compact system installation

with PDD 25 metering screw and

PH-ZS 150 pharma-design

rotary airlock feeder

200 ZPS clean room

installation

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

sPiral Jet mills

and Particle

as - Just Fine!

Spiral jet mills are used for the easy to inspect and clean. As

ultrafine comminution of dry spiral jet mills do not generate pharmaceutical substances. heat during grinding, even

Typically, particle sizes in the heat-sensitive materials can be

range of < 5 – 40 µm are achieved.

comminuted without problems.

The benefits of spiral jet mills are Spiral jet mills are not suitable

in their simple design without are often not suitable for sticky

moving parts, which makes them products of for applications

are prone to sedimentation or

for applications that require a

controlled, steep particle size

distribution. For these cases,

we recommend fluidised bed

opposed jet mills. Smooth

- Typical area of application:

grinding of products with

micronising in the range of < 5-40 µm

agglomerates in the batch to be

- Simple design – easy inspection and cleaning

processed require pre-crushing.

- No moving parts

- No heat generation

- Pre-crushing to < appr. 2 mm is necessary

For R&D application

- Broad particle size distributionng

400 AS spiral jet mill

PrinciPle oF oPeration

Pharma range

The AS is a spiral jet mill designed desired fineness. The mill settings for dry grinding soft to medium-

can be adjusted by varying the

hard materials. A number of air grinding air flow rate, .air flow nozzles generate an air vortex that

rate and the grinding gas pressure.

rotates at high speed. The feed material is fed to the grinding

chamber via an injector assembly.

AS spiral jet mill range

Number of nozzles

Nominal air flow*

comminution is the result of

inter-particle collision caused by the different velocity gradients

in the air flow. The grinding air is extracted by means of a dip

pipe located in the centre of the grinding chamber. Because of the

free vortex, a classifying effect is

generated, meaning that only fine particles can exit the mill through

the dip pipe and be collected in a filter. coarser particles remain in

the grinding chamber until such time as they have reached the

* at grinding pressure of 6 bar g

100 AS detail

315 AS module with PDD 30 double

metering screw

Smallest AS for R&D processing of mini

batches at maximum output (mg + g) with

the Piconizer®

Isolator-integrated 100 AS

140 AS sterile system

Throughput

End-product fineness kg/h

Machine size

90 % < 2.4 µm

Disposable mill

97 % < 3.8 µm

97 % < 4.1 µm

97 % < 5 .2 µm

Plastic lining parts of the 100 AS

Powder fineness in % < µm – measuring points of particle size distribution

All values are non-binding reference values only

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

Fluidised bed

and Particle

oPPosed Jet mills

aFg – ultraFine and sharP

area oF aPPlication

In addition to the tried-and-tested spiral jet mills for the production

of ultrafine end products, fluidised bed opposed jet mills with

their special housing geometry and the integrated classifier offer a

significant technological benefit: the dynamic classifier ensures a high

separation accuracy for an absolutely pure top cut which is free of

oversized particles. changes in the fineness setting can be achieved

- Typical area of application:

easily and reliably thanks to the frequency-controlled classifier drive.

micronising in the range of < 4 µm – 150 µm

compared to spiral jet mills, this approach allows a very broad setting

- Accurate fineness setting

range of between about 4 µm and 150 µm (d97). This type of mill is

- Sharp top cut control

suitable for products that are prone to sedimentation.

- Steep particle size distribution

- No heat generation

PrinciPle oF oPeration

- Suitable for products of sticky or

The AFG is comprised of two components – the classifier head and

the grinding chamber with integrated nozzles, the number of which

- No abrasion/wear

depends on the mill size. The material particles entering the jets are

accelerated and collide with each other in the focal point where the jets of air intersect. comminution occurs due to inter-particle collision

Pharma range

in the focal point and because of shear flows at the edges of the air jets. As a result, the risk of contamination due to abrasion is virtually non-existent. A high-performance Turboplex classifier discharges the

end product from the internal grinding process to a separator system (cyclone or jet filter). The fineness can be set by adjusting the air flow rate, the grinding air pressure and the classifying wheel speed.

Fluidised bed opposed

jet mill range (AFG)

Nominal flow rate*

* at a grinding pressure of 6 bar g

280 AFG fluidised bed

opposed jet mill

200 AFG Installation

for pharma lactose

100 AFG Compact Pharma System

100 AFG Isolator integration

End-product

Throughput

fineness

Machine size

140 AFG - Installation in clean room wall

Salbutamol sulphate

Powder fineness in % < µm – measuring points of particle size distribution

All values are non-binding reference values only

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

mPs – unbeatable versatility

area oF aPPlication

In the wake of the steady flow of newly developed products with

unpredictable grinding properties, mills have to offer maximum

versatility. This is the objective of so-called multi-mill systems, which

offer the perfect solution to changing requirements. Multi-mill systems

are mobile, very versatile concepts where two or more different mill

types are integrated into one ancillary installation, allowing a quick

change-over between the required units.

- Different mill types share the same

ancillary equipment

- Highly versatile for production

of different products

- Fast change-over

- Reduced capital expenditure

- Reduced documentation and

validation requirements

200 AFG 100 ZPS

multi-process modular system:

The following modules can be used alternately:

PrinciPle oF oPeration

- AFG fluidised bed opposed jet mill

The size of the installation is based on similar batch volumes,

- ATP ultrafine classifier

product throughputs, process gas flow rate, etc. The configuration

- zPS classifier mill

allows different metering systems, fittings, drives, product filters,

- AS spiral jet mill

ventilators, etc. to be used. The benefits are obvious: in addition

- uPz fine impact mill

to a high level of versatility – retrofitting is also possible – capital

expenditure, documentation and validation requirements are reduced to a minimum. Multi-mill system combinations can be used both on an R & D (Picoline®) and on a production scale.

Module 100 UPZ

Module 100 AFG

Disconnect 100 AFG

Detail technical area

Multimill Isolator Integration

100 AFG 50 ZPS Multi mill

Cone MillExchange of Mill Modules

within technical area of isolator

For R&D application

multi-mill –

combination oPtions

The ultimate

multi-mill

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

agitated media mills

ahm – wet grinding

at its Finest

Grinding example: fenofibrate

wet grinding down to nanoscale siZe

The amount of poorly soluble pharmaceuticals among NcEs is on the

Particle Size (µ 0,3

increase. New drug delivery methods are required to help increase

the bioavailability of these substances. The ultrafine grinding of

particles down to nano-scale size with the help of agitated media

Specific grinding energy (kWh/kg)

mills is one way of improving their bioavailability. This approach opens up a range of additional benefits: accurate dispensing,

minimised volumes and fast effectiveness. The minimal volume of

- Grinding of insoluble APIs in the submicron and

nanosuspensions in syringes improves the injectability of the drug

and minimises sedimentation problems.

- Versatile, exchangeable wear protection

elements (ceramics, plastic) possible

- Easy to clean, GMP design

- Double-action mechanical seal

- Sterile equipment option

For R&D application

PrinciPle oF oPeration

Pharma range

The AHM is an agitated media mill designed for the continuous or batch-operated wet ultrafine grinding of particles in solution. The grinding chamber of the mill is usually filled with ceramic grinding beads which are set into motion by a rotating agitator. The feed product is suspended in a fluid and is conveyed through the grinding chamber by means of a pump. comminution is a result of the friction caused when the feed particles impact against the agitated grinding

Grinding chamber (l)

beads. In continuous operation, the suspension exits the mill after passing through the grinding zone, while a screening element retains

the grinding beads in the mill. The fineness level is set by adjusting the rotor speed, the filling ratio of grinding beads in the mill and the

suspension flow rate, as well as by selection of the grinding bead size.

Mill equipment in various

construction materials

agitated media mills

50 AHM

Picoliq

200 AHM

In pharma-design

90 AHM

Complete installation

Specific grinding

Machine size

50 AHM (Picoliq)

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

some like it coarse

Pre-crushers: practical examples

Pharma-design ha 20/10 hammer mill

Pharma-design laboratory hammer mill for the size reduction and

disintegration of agglomerates and lumps producing an end-product

fineness of < 500 µm with minimum fines. Depending on the project,

the mill can be delivered integrated into an isolator.

- Disintegration of agglomerates and lumps

of up to <500 µm

- Processing of soft and medium-hard

- Easy cleaning/dismantling

- cantilevered bearing

- Purged pharma bearing

Pharma range

For R&D application

Rotor diameter (mm)

Number of beaters

Pre-crushers: Practical examPles

End-product

Throughput

97 % < 1.000 µm 70

50 % < 100 µm

Nacl (table salt)

DB pre-crushing range

Sieve grate gap* (mm)

Lumps of about 100 mm

* = depending on the application

Powder fineness in % < µm – measuring points of particle size distribution

All values are non-binding reference values only

db 500 Pre-crusher

crusher for soft, slightly

20/12 RO detail

crumbly materials and lumps. Ideal for disintegrating and aerating agglomerates and for

processing lumps. Typical areas of application include the size reduction of agglomerated excipients and additives after transport or storage. Easy and compact installation. Available with sieve grate gaps of 12 mm and 18 mm.

Pharma-design rotoPlex

ro 20/12 granulator

Pharma-design granulator for

pre-cutting pharmaceutical and

chemical products. The granulator

has a twin-knife rotor and a three-

knife stator. A range of different

Pharma range

screen inserts allows definition of the maximum top cut.

Rotor length (mm)

Maximum rotor speed

* = depending on the application

Practical examPles rotoPlex

End-product

Throughput

Machine size

- Size reduction of materials

Medicinal herbs, stalks

suitable for cutting such as

Medicinal herbs, flowers

medicinal herbs, fibres, and

polymers to end-product fineness < 1 – 2 mm

96 % < 3.15 mm

- Pharma/GMP-qualified design

Granulated pharma

16 % < 250 µm;

- compact footprint

Powder fineness in % < µm – measuring points of particle size distribution

All values are non-binding reference values only

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

metering systems – it all

dePends on the dosage

- GMP-qualified design

Pdd Pharma double Feed metering screw

- Modular configuration

- clear division between product-contact

Hosokawa Alpine develops its

own system components to

- Easy to dismantle, i.e. easy to clean the

suit the special requirements

product-contact zone

of pharmaceutical applications

- Product-contact components can be

and guarantee the compliance

autoclaved when pre-assembled

- Optional volumetric or gravimetric metering

The ALPINE PDD double feed

- Special design for isolator integration

metering screw is a twin screw

in continuous operation for the accurate metering of dry substances. The complete screw

Feed screw range

comprises the following modules:

- different agitator and screw

geometries available

Filling station with PDD

- volumetric and

35 (SIP) for isolator

gravimetric design

- containment solution

for isolator integration

Module 1 – drive unit

Screw drive with Dc motor, fully integrated into a stainless-steel housing.

Module 2 – bearing unit

Screw bearing in closed monobloc

housing with bayonet catch and

lip sealing.

Module 3 – product container

Screw housing in monobloc

design with integrated mixer.

Pharma micro dosing screw Pmd

We offer metering solutions especially for pharmaceutical applications.

Minimum metering rates and residue-free dosage of very small batch

sizes is a major challenge.

The ALPINE PMD micro dosing screw is a volulmetric feeder in

continuous operation for the accurate metering of minute volumes

and is suitable even for substances with poor flow properties. The

special design reduces product residues to a minimum.

Pharma – Pdr metering channel

The ALPINE PDR is a volumetric vibration feeder in continuous in con-

tinuous operation for the accurate metering of free-flowing products.

range oF vibration Feeders

Open vibration chute - for lab applications

closed vibration pipe Ø 32 mm

Micro Dosing Screw

closed vibration pipe Ø 100 mm

PDR

feed chute

PDR 32

Vibration pipe

PDR 100

Vibration pipe

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

more than

Just accessories

Zs 150/200 rotary valves

ALPINE zS 150/200 rotary valves are used as rotary

feeders, discharge devices, barriers for pressure-

shock-proof installations and air/gaslocks. They

are specially designed for compliance with cGMP

requirements and are therefore characterised by

their ease of dismantling and cleaning. They also

allow force purging of bearings and housing covers.

ZS 200

Installation in

clean room wall

- cGMP-qualified design

- Modular configuration

- clear division between product-contact

- Easy disassembly, i.e. easy cleaning

of all product-contact areas

- Product-contact components can

be autoclaved when pre-assembled

- 10 bar pressure-shock-proof and

flameproof designse

- Gas-purged bearing and housing cover

- Alternative rotor chamber sizes

range oF rotary valves

* clamp DIN 32676

DN 50 EzConnect

alPine eZconnect comPensators

dn 50 – dn 300

Hosokawa Alpine's compensators are made from a single piece of silicone and a hygienic tri-clamp connection as an additional part.

other Features:

- Suitable for operating temperatures of between -20°c and +140°c

- Explosion protection: suitable for use up to zone 20

- Suitable for operating pressures of between -0.25 bar to +0.5 bar

- Simple, hygienic tri-clamp connection

- clamp connections made from stainless steel AISI 316 L

- The compensator is made either of EPDM or silicone and complies

with FDA directive 21 cFR § 177.2600

- The support rings are a principal part of the compensator- (no loose parts, very easy assembly)

Installation length max. compensation Diameter

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

trust, but veriFy

Process automation

Autmation by Hosokawa Alpine is process technological expertise

translated into software and hardware. A team of experienced

electrical engineers develops the basic principles of our automation

technology and ensures the perfect interaction of all module interfaces

and end-to-end documentation of all modules.

Process visualisation

The process sequences and process parameters are represented

Hosokawa Alpine offers optimal process solutions.

graphically on-screen. The system flowchart forms the basis of process

Process technology and automation engineering are

display; it is formatted, animated and supplied with the required

tailored to customer requirements and come from

process parameters. It is important that the flowchart is easy to read

one single source.

and that process sequences are easy to follow. colour-coding is used

system automation has significant

to highlight important information, while less important information

is displayed in the background. The process is also operated on-screen.

- Overview of the complete system condition at

The user interface has a simple, logical design, user navigation of the

menu structure is highly intuitive. This prevents operating errors and

- Menu navigation for the operating modes

avoids additional training requirements.

- Process operation

- cleaning operation

exPertise in Process engineering

Process engineers and electrical engineers cooperate in developing the

- Process data memory

best solution for each customer. Modular automation components are

- Trend visualisation

individually combined, depending on the process and the customer's

- Alarm archiving

automation requirements. customers benefit from our process

- Password administration

- Recipe management

- configured in compliance with

GAMP 4/5 and 21 cFR Part 11

count on us!

upon receipt of the uRS, the characteristic process data such as the end-product fineness and throughput rate, etc.

The user Requirement Specification

are determined, and the system-specific parameters such as

(uRS) provides us with the customer's

construction materials and surface qualities, etc. are defined.

main system specifications, i.e. the

The resultant system configuration is checked during the

grinding system requirements.

subsequent qualification phase for compliance with the uRS.

Process imPlementation

alPine testing centre

alPine rental equiPment

Alpine's testing centre offers unique facilities for carrying Following acceptance of the layout, manufacturing drawings

out customer trials aimed at finding the best possible system are prepared and, if required, special solutions are developed.

design and at determining the technical warranty parameters.

If occupational safety restrictions prohibit the processing of manuFacture / assembly

materials at the testing centre, we can offer a range of rental Manufacture, assembly, wiring and connection to the control

systems which can be installed and operated at the customer's unit are carried out on Alpine's premises, which ensures the

site. This way, customers can gather their own experience with

perfect interaction of all interfaces.

the machines and compile their optimum uRS.

design study

The executed quality of the system is inspected by means of

Based on our experience and in close cooperation with our factory and site acceptance tests (FAT/SAT). compact systems customers, we develop a system concept which is tailored to the

are completely assembled on Alpine's premises and subjected

customer's requirements and which illustrates ergonomic aspects.

to a FAT, which reduces the effort for the SAT to a minimum

commissioning / training

This service is available if required, e.g. for complex projects Alpine supports its customers during system commissioning and involving isolators, we create a 1:1 wooden model that allows

provides training for the operating personnel.

simulation of all important process steps with original components wherever possible.

PROCESS TECHNOLOGIES FOR TOMORROWSM

+++ Powder

and Particle

1. Powder and Particle Processing

Hosokawa is the world's largest supplier of processing systems for

Hosokawa Alpine has been in business for

the powder and particle processing segment. Renowned names

more than 100 years, and we have been

such as Alpine, Bepex, Stott, Vitalair, Rietz, Mikro, Micron and

setting the standards, regardless of the

Vrieco-Nauta are all part of the group's product range. Regardless

segment, be it blown film production or

of the size, be it production-scale system, pilot system or laboratory

powder and particle processing. The chal-

equipment, Hosokawa's products and technologies are used at

lenges of market leadership and our ex-

numerous production stages, e.g. for size-reduction, mixing, drying,

perience inspire us to aim for a constant

agglomeration, classification, weighing and metering.

refinement of our technologies.

2. blown Film lines

Hosokawa Alpine is one of the world's foremost suppliers of blown

film lines. Alpine supplies complete systems for blown film production

and processing from a single source, from granule feeding systems to

film winders, from single-layer die heads to 7-layer lines, from simple

speed regulators to state-of-the-art process control systems. Thanks to

Alpine's film orientation lines, the company can now offer complete

systems for film conditioning.

3. conFectionery & bakery technology

Benefiting from the vast expertise of companies such as Bepex, Kreuter

and Ter Braak, Hosokawa confectionery and Bakery is the ideal partner

for the confectionery industry. A complete range of machines and

production systems is available or can be tailored for the requirements

of every stage of the production chain, from preparation of the raw

materials and confectionery pastes to the end product.

Process technologies For tomorrowsm

divisional structure

The name Alpine stands for expertise in all areas of size-reduction technology. After many years of close

cooperation between our engineers and our customers' R&D departments, we have become the world's

leading specialist for powder and particle processing. In order to ensure that customers from different

industrial segments receive professional assistance and consultancy, our particle processing division is

divided into five subdivisions:

Pharma & lab

minerals & metals

Producing powdery substances for the We provide complete dry and wet processing pharmaceuticals industry requires the skills and systems with state-of-the-art mills and classifiers for experience of experts. Hosokawa Alpine complies processing mineral raw materials. Our machines and with international pharmaceutical standards and systems for processing fillers, ceramic raw materials, supplies a wide range of products and services, metallic compounds and alloys meet the exacting including laboratory applications and special requirements of our customers.

processes. Whatever size reduction method is required, we are the specialists.

recycling & granulators

We design, engineer and deliver complete granulator

systems which include all required system components.

The range of chemical products is as diverse as the Be it for injection-moulded parts, sprues, film webs different demands on pigment or powder properties.

and edge trimming, our granulators are designed for

We provide process engineering solutions for the the most challenging tasks.

chemicals industry from a single source. We also

offer competent consultancy on basic chemical Food

products and auxiliaries, toners, paints, pigments, The food division develops special food processing

herbicides and fertilisers.

techniques and supplies complete production lines for sugar, cocoa, lactose, proteins and spices.

service

Our service division provides support throughout

the entire life-cycle of Hosokawa Alpine systems

or machines. Our comprehensive service package

includes spare parts supply, servicing, inspection,

maintenance, repair, general overhauls, system

upgrades and training. A recent addition to our

service range is the supply of pre-owned Alpine

machinery.

Hosokawa Alpine is at your service – no matter

where you are and what your processing challenge

is. Our service range includes project management,

installation, commissioning, training, maintenance

and system optimisation.

PROCESS TECHNOLOGIES FOR TOMORROWSM

HOSOKAWA ALPINE Aktiengesellschaft

P.O. Box 10 11 51

Address for visitors and deliveries:

Peter-Dörfler-Strasse 13 – 25

+ 49 821 5906-283

+ 49 821 5906-620

Subject to change without notice. All data in this

brochure are purely informative and without

guarantee as to correctness. Authoritive for

orders are our quotations.

Hosokawa Alpine is a member of the Hosokawa Micron Group, a high-perfor-

mance manufacturer of systems for powder and particle processing, systems

for the confectionery industry as well as plastics processing machines and

systems. The group is known and reputed the world over for its power of inno-

vation, constant product care and market-oriented R&D. The most important

group resources are R&D, engineering and manufacturing as well as customer

service in all global markets.

Hosokawa Alpine 2013. Printed in Germany.

Pharma 04.13/1(EN)

Source: http://www.teknol.eu/wp-content/uploads/2013/12/Pharmaceutical-technology-GMP-size-reduction-systems1.pdf

Authored by the DIGITAL DERMATITIS (HEEL WART) Digital dermatitis (DD) is a multi-factorial superficial dermatitis of thedigital skin of cattle. The mostcommon site is the palmar/plantarinterdigital ridge of the foot—especially the rear feet (Figure 1),but other sites include the skin of theinterdigital cleft, the heel, sometimesunder-running the sole, and thedorsal aspect of the coronary band(Figure 2), where they may beassociated with a vertical wall crack.

Journal of Aquatic Biology and Fisheries Vol. 2/2014/ pp. 133 to 140 ANTIDIABETIC AND ANTIOXIDANT ACTIVITY OF PADINA TETRASTROMATICA IN HIGH CALORIE FED/STREPTOZOTOCIN TREATED RATSDivya S. Mohan, Mini Saraswathy, Muraleedhara Kurup and Gopala Kurup* Department of Biochemistry, University of Kerala, Kariavattom Campus,