Viagra gibt es mittlerweile nicht nur als Original, sondern auch in Form von Generika. Diese enthalten denselben Wirkstoff Sildenafil. Patienten suchen deshalb nach viagra generika schweiz, um ein günstigeres Präparat zu finden. Unterschiede bestehen oft nur in Verpackung und Preis.

Dppharma.ir

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

This Site Master File was prepared on the basis of the PIC/S document "Explanatory notes for industry on

the preparation of a Site Master File" PE 008-4.

Contents:

Chapter 1: General information

1.1

Contact information on the manufacturer

Authorized Pharmaceutical manufacturing activities of the site

Any other manufacturing activities carried out on the site

Chapter 2: Quality management system

2-1

the Quality management system of DAROU PAKHSH PHARMACEUTICAL COMPANY

Release procedure of finished products

Management of Supplier s &contractors

QRM(Quality risk management)

Product quality reviews

Chapter 3: Personnel

Organization of technical division

Chapter4: Premises and equipments

4-1

4-1-1 Brief description of heating, ventilation and air conditioning (HVAC) systems 4-1-2 Brief description of water systems 4-1-3 Brief description of other relevant utilities, such as steam, compressed air, nitrogen, etc. 4-2

4-2-1 Listing of major production and control laboratory equipment with critical pieces of equipment

identified should be provided in Appendix 8

4-2-2 Cleaning and sanitation 4-2-3 GMP critical computerized systems

Chapter 5: Documentation

Chapter6: Production

6-1

type of products(reference to appx. 2)

Process validation

Material management and warehousing

Chapter 7: Quality control(QC)

Chapter 8: Distribution ,Complaints, product defects and recalls

Chapter 9: Self inspections

Page 1 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

General appendies

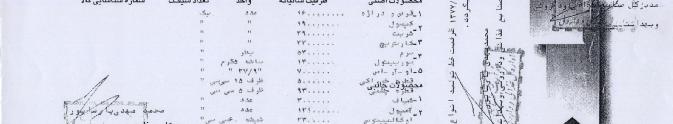

Appendix 1: Copy of valid manufacturing authorization

Appendix 2: List of dosage forms manufactured including the INN-names or common name (as available)

of active pharmaceutical ingredients(API) used

Appendix 3: Copy of valid GMP Certificate

Appendix 4: List of contract manufacturers and laboratories: NA

Appendix 5: Organisational charts

Appendix 6: Lay outs of production areas including material and personnel flows, general flow charts of

manufacturing processes of each product type (dosage form)

Appendix 7: Schematic drawings of water systems

Appendix 8: List of major production and laboratory equipment

Page 2 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

Chapter 1: General information

DAROU PAKHSH PHARMA. MFG. CO is a subsidiary of Tamin pharmaceutical investment company

(TPICO). which is a wholly owned subsidiary o f Social Security investment Company. This company is a

registered public joint stock company according to the I.R. Iran laws.

1-1

Contact information

Name: Dr.Amjadi Kambiz(senior manager)Dr. Eimagh naeini Babak&Dr. Dolat abadi

Fateme&Dr.zamani farahani Afsane&Dr.Ahmadi Zahra.

Address: 18th Km of karaj freeway , Darou Pakhsh Manufacturing pharmaceutical company ,Tehran ,Iran

P.o.Box:11365-4388

Phone:(+98-21)44986815-16

Fax: (+98-21)44987314

Email:

1-2

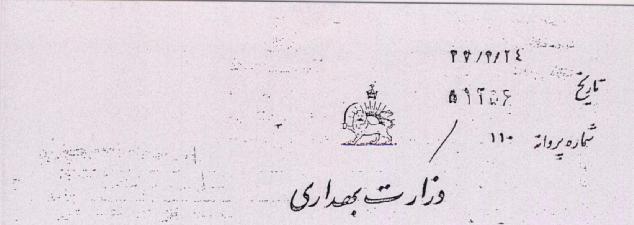

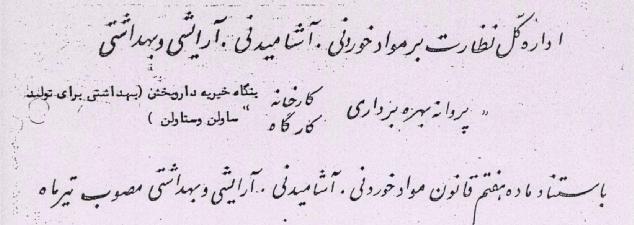

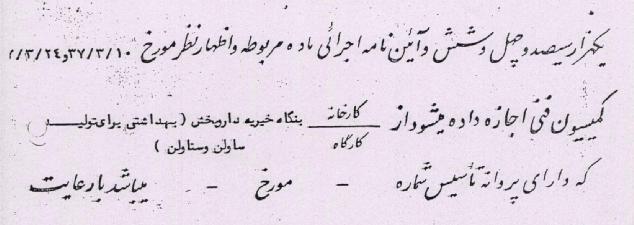

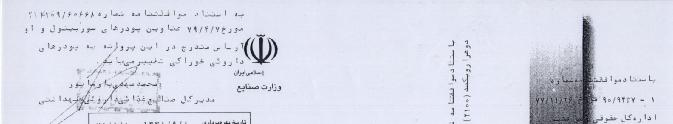

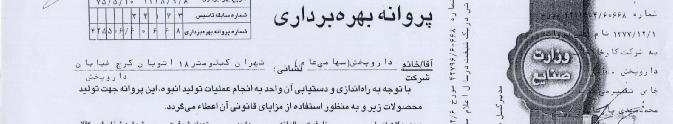

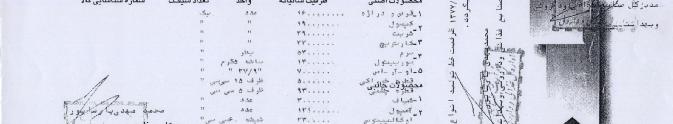

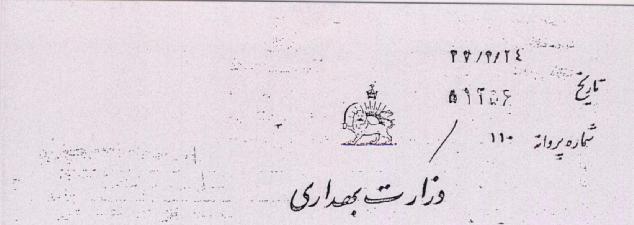

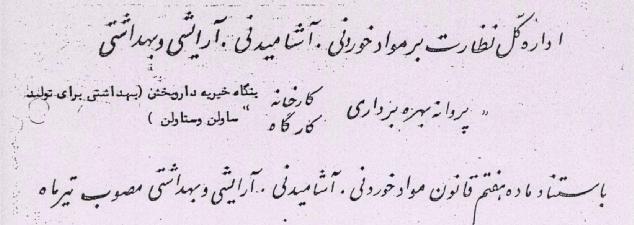

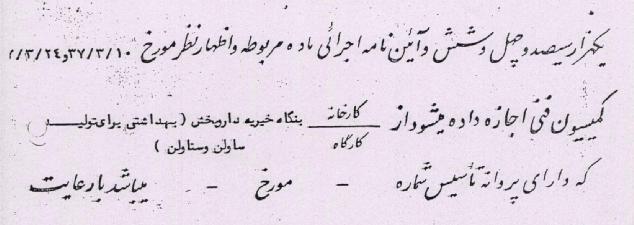

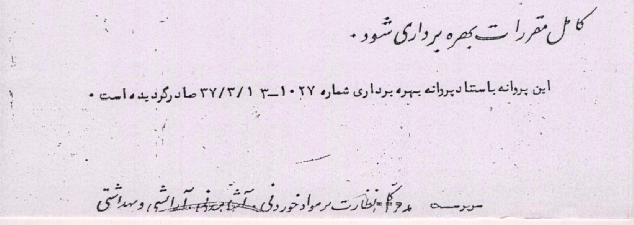

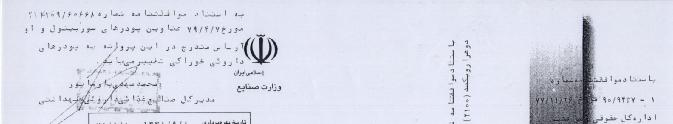

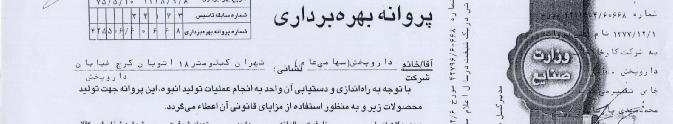

Authorized Pharmaceutical manufacturing activities of the site

DAROU PAKHSH PHARMA. MFG. CO. is authorized by MOH of I.R. Iran (n° T42-74), date August 15,

1972 and ministry of Industry (n° 42- 06/60668), date Nov. 30, 1959 to manufacture, import, trade

wholesale and export medications (Appendix 1)

DAROU PAKHSH PHARMA. MFG.CO. manufactures more than 176 pharmaceutical finished products

for human and veterinary in different dosage forms: tablets, capsules, oral powders (sachets), oral liquid,

small volume parentherals (SVPs)& large volume parenterals (LVPs), Freeze dried injectables, eye-drops,

creams, ointments and suppositories, lotion, vial and dental cartridges.

For human products, manufacturing licenses are obtained from Iranian Ministry of Health (MOH). In

addition, for veterinary products, the appropriate Licenses are obtained from the veterinary organization of

Ministry of Agricultural. (Appendix 1)

The company is located in suburb of Tehran ; research and development activities , manufacturing , quality

control , marketing and dispatch activities are all carried out at this site. Recently dedicated production

areas e.g. Insulin, Mycophenolate and contrast media are added.

1-3

Any other manufacturing activities carried out on the site

The company imports nutritional supplement products and may produce cosmetics or cosmeceutical

products in future.

Chapter 2: Quality management system

2-1

the Quality management system of DAROU PAKHSH PHARMACEUTICAL COMPANY

DAROU PAKHSH PHARMA. MFG. CO. considers quality in the wide sense of the word as being one of the key-elements for its success. DAROU PAKHSH PHARMA. MFG. CO quality system design and implemented with the aim of producing high quality, healthy and effective drugs in accordance with the principles of GMP,. , the.Product quality improvement (in aspect of the customer) and the standardization of products and processes (in the way processes) are determined.as sterategic goals of company. In this regard, the company in the year 2002 towards the establishment of the ISO 9000 system action and in2010 compared to the revision 2008. Improving quality system, as the unlimited process, has done under the leadership of the Managing Director, restrict.

Page 3 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

The site operates in conformance with GMP /PICs.

A fully documented quality system is established and maintained which ensures that products, produced,

released and sold meet the specified requirements of the relevant specifications .

Senior Management Reviews are held and use Internal Audit results, deviations,CAPA's, external audits to

determine the effectiveness of the quality system.

The Quality system include quality assurance unit,quality control unit and responsible pharmasists are

directly responsible for all aspects of the quality system including, but not limited to:

§ approval or rejection of all raw materials, components, and product batches,

§ ensuring the CAPA system is functional,

§ ensuring that maintenance and calibration systems for critical equipment are effective,

§ oversight of cleaning and sanitization systems,

§ cGMP training,

§ ensuring that quality related customer complaints are investigated and resolved,

§ organizing and monitoring recalls, and performing product quality reviews products throughout

The specifications for raw materials and finished products as well as for manufacturing and analysis

processes are set out in written procedures, which are periodically controlled.

Written reports are kept on manufacturing conditions and on the controls undertaken during manufacturing

and in the laboratories. This permits monitoring of the company's manufacturing and guarantees their

quality.

The company has certificate of ISO14001&9001 .(Appendix 1)

2-2

Release procedure of finished products

The batch may not be dispatched unless it has been released and is accompanied by a duly signed

certificate of analysis

Quality Unit personnel authorized to review batch documentation and release batches are by responsible

pharmacist of the Quality Control department for the intermediate and finished products.

The batch certification and release procedure is covered by DPWI6377009 Batch Release.

In summary, the person in charge of release reviews all pages of the completed production batch record

and the test sheets from the QC lab to ensure that all parameters were within specification, all spaces for

entering information are completed, signatures and production checks were completed, raw material

usage data is correct and complete, labels are accounted for and excess labels are destroyed, and

calculations are verified If all information is in order, the batch record is stamped "RELEASED, BY,

and DATE". Then the batch is released . None of the current control strategies Process Analytical

Technology (PAT). employ

2-3

Management of Supplier s &contractors

The evaluation of suppliers takes into account in various criteria: § The history of the company's relations with the supplier § The quality of products supplied hitherto § cGMP and ISO 9001 certification is a selection criterion (for similar offers, preference is given to a

supplier with such certification)

§ Results of external audits undertaken by Technical director in collaboration with Industrial Logistics. Emphasis is placed on the audit of the major suppliers whose products have a significant impact on the quality of DAROU PAKHSH PHARMA. MFG. CO. finished products.

Page 4 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

The production unit is responsible for ensuring production deviations are reported and considered; critical

deviations are investigated with conclusions and corrective actions documented,

The production unit also is responsible for ensuring the production facilities are clean in

accordance with site production and quality procedures, ensuring that calibrations are performed and

documented,

ensuring that facility and equipment are maintained and these activities are documented ,reviewing and

approving validation protocols and reports, reviewing and approving changes to products, processes, and

equipment, and ensuring that new and modified equipment are qualified as appropriate.

2-5

Product quality review

Annual Product Reviews are completed for API's and semi-finished medicinal products

Site Manager, Production Manager, Process Manager, Quality Control, and Quality Assurance reviewed

and discussed the results of all APR. The studies contain a product summary (number of batches

produced, specifications), description of deviations (in-process deviations, complaints, OOS's, etc.), a

description of change control documents, specifications and revisions, review starting and packaging

materials, process validation review, equipment and utility review, test data analysis and trends, stability

review, recalls, conclusions, and recommendations. Site meetings are held where corrective action plans

are generated where necessary.

Chapter 3: Personnel

The organization chart provided at appendixe5, outlines the structure of DAROU PAKHSH PHARMA.

MFG. CO. top chart.

3-2 The technical staffs are deployed as follows:

Production:

Quality control:

Regulatory Affair 8 QA:

Training strategies and policies are set according to organization's strategy and the human resource development requirements; thereby the training total program is set out. The job training needs and the main content of courses are determined through interview with subject professionals and modified periodically by job professionals in company. The employee training needs for each personnel and the training priorities are determined by questionnaire and interview with manager and direct responsible of employees, annually. All the personnel whose jobs could affect the quality of the product (Production, Maintenance, Storage, Quality Control) receive GMP training that include issues such as pharmaceutical products quality, personnel, sanitation and hygiene, premises and equipments, materials, documentation. Newly recruited production personnel (either permanent or temporary employees) receive induction training that covers good practices in production and packaging the different pharmaceutical dosage forms as well as health and safety. The quality control staffs receive previously mentioned training as well as GLP.

Page 5 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

Subjects such as GMP, which the legal obligations require their retraining, are retrained timely. The

specialty issues are retrained in updated cases, which are determined at annually need assessment or are

requested by managers.

Health & safety and environment unit under supervision of Human Resource Department is responsible for

checking employee's health & safety and hygiene. Base on person's job and work place hazard DAROU

PAKHSH PHARMA. MFG. CO. has especial physical examination interview and Para-clinic tests

(Eudiometry, Spirometry, Optometry and.). There is periodic employee examination base on their job.

DAROU PAKHSH PHARMA. MFG. CO. has special sickness registration system that report yearly.

For hi-risk jobs there are special protocols for following and all employees have special examination before

and during their work. DAROU PAKHSH PHARMA. MFG. CO. has special registration system for

worker during return the work after disease. Those who work in aseptic and clean areas have clinical

examination twice a year and examination has different.

QC clothing in the laboratory is white. Standard clothing in the production buildings is a blue overall, a

cap/hat and working blue shoes or overshoes. Mechanics who undertake dirty work wear dark blue

overalls.

Overall are washed and pressed once a week inside the company; each collaborate has a set of 2-5 overalls,

permitting once change.

Depending on the type of work and its localisation (for example laminar flow, aseptic arias, controlled

arias, etc) each collaborator wears specific clothing (for example sterilised overall, mask, hood, specific

shoes and gloves).

Chapter4: Premises and equipment

4-1

premises

DAROU PAKHSH PHARMA. MFG. CO. is located in the suburb of Tehran with more than ……. buildings on a 191/650 m2 (see location site in appendix6). Floor plans are provided in the Appendix 6 The premises are situated, designed, constructed, adapted and maintained in a manner to facilitate manufacturing, control and cleaning operation. Manufacturing, packaging, quality control and storage operations are undertaken in buildings. The Main production building from 1959 houses mainly pharmaceutical production and R&D & quality control laboratories From 2010 , renovation have been done in main production buildings under latest GMP and environmental standards for example sterile production unit and liquids production unit and QC laboratories departments have been done Also 3 new production units have been constructed : 1) Insulin production line 2) Growth hormone production line 3) Vial production line In near future , packaging of solids unit , central weighing departments and semisolids unit will be renewed. Training center & Clinic buildings These buildings are located outside of the production area and used for personnel training and healthcare.

Page 6 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

4-1-1 HVAC SYSTEM:

Each unit has its own separated HVAC and if necessary dedusters. In all units fresh air is available

according to unit requirements and in solid unit full fresh air exists. HVAC's have F9,F7 & G4 and in case

of GMP guidelines H13 filters .

Tempreture , pressure and humidity are monitored and control system creats optimal conditions

4-1-2 Water systems

Water that derivated from well after passing sandy filters is chlorinated by DP(Darou pakhsh) to 0.6ppm.

Chlorinated water is used for general consumption in the company. All units are equipped with pure water

generator which turn the chlorinated water to pure water by RO equipments.

The input water for RO passes through carbon filters for dechlorinating & water softner for reducing

hardness and after passing through membrance filters turns into pure water.

If injectable water is needed, it can be produced from pure water and distillation process.

The water specifications for this unit are those set out in the BP monograph

4-1-1 Steam /Compress air/ Oxygen/ Nitrogen:

Compressed air :

Compressed air is generated by 2 oil-free compressors that work frequently. It is stored in storage tanks

through dryers and then transferred to all units via pips for their usage. All the compressors and

requirements are located in main power plant of the company

Steam:

There is 2 kinds of steam system in DP :

1) Industrial steaming in which steam is generated in the boilers and then transferred through pipes to all

2) Clean steaming in which by using industrial steaming and pure water in the unit itself, clean steaming is

producer and used.

-The available oxygen in compressed air after passing through oxygen generator is separated from

Nitrogen with the purity of 99% and stored in feeding tanks and reached to units that need pure oxygen

vice pipes. This generator is located in the main powerplant of the company

-Nitrogen:

The available nitrogen is compressed air is separated from oxygen with purity of 99.5% when passes

through Nitrogen generator and is stord in storage tanks. This Nitrogen transfer to those units in need of it

via pipes. This generator is located in main powerplant of the company.

4-2

Equipment

The materials used for the construction of apparatus machines used in production are appropriate for their

use (for example, various types of stainless steel); flexible silicon pipes can be sterilized. Production

phases requiting aggressive treatments (for example alkaline) are undertaken on materials resistance to

such conditions.

4-2-1 Description of production and control equipment

The Lists of major production and control laboratory equipment are in appx. 3

Page 7 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

4-2-2 Equipment cleaning

The manufacturing areas are cleaned and if necessary disinfected after each manufacturing run by the

manufacturing personal according to the current operating procedure.

Large pieces of apparatus are designed to facilities cleaning and/or sterilization in place; small or easily

dismantled pieces of equipment are cleaned by hand or in washing machines (glassware) before being

disinfected or sterilized, if necessary.

The cleaning of the HVAC systems is undertaken regularly with a varying frequency variable depending

on the type of installation.

The microbiological laboratory monitors the microbiological quality of the air in the different

manufacturing and control premises.

The frequencies of the controls and the limits set for warnings / actions depend on the type of premises.

A microbiological control of the surfaces is also undertaken in the atmosphere – controlled areas.

4-2-3 Electronic monitoring systems:

These systems function as logical control by using PLC. (Programmer logical controller)and HMI(Human

machine Interface) that ultimately lead to control.

EMS system for monitoring and controlling of environment conditions can be accessible locally as well as

an Internet and local Intranet.

Systems for checking staff personnel , materials and products can be programmed by Access control on the

network and assure that only authorized personnel can have access to certain units.

Chapter 5: Documentation DAROU PAKHSH PHARMA. MFG. CO. has established a document

management system. This system organize the different types of documents, i.e.

§ Quality Manual

§ process profiles

§ instruction&/or procedures of doing the process

§ the process instruction &/or procedures of controls and monitoring

§ Recordes and documents of above

Control of Documents

Quality system documents are controlled both manual and semi electronic. the format, Coding, content, approval, distribution, revision, and control of documents describes in procedures and ensures that only the most current versions of quality system documents are used. Procedures are in place for manufacturing processes, the quality control laboratory, and all general site quality procedures. Each controlled procedure is assigned a unique document number, and each document contains the effective date, revision number, expire date(valid until) signature blocks for the issuer and approvals , QA manager, and a revision history. Responsible pharmacist's signature required for all documents pertaining to production as defined within the document control SOP's.

Control of Records

Procedures for filing, storage, and disposal of quality system records are defined in the Quality Records Management Procedure (DPPR424007). All written operating area and laboratory records are completed during activities The following are described in the documentation:

Page 8 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

Product specification

Raw material specification

Packaging material specification

Operating procedure describing the different manufacturing steps, including packaging

Analytical methods

Procedure for batch release

The documents for follow-up of manufacturing and analysis, which constitute the batch process

record(BPR).

The BPRs are revised and controlled by the heads of manufacturing divisions, thus certifying that the

batch has been manufactured according to the operating procedures, that all the manufacturing process

controls have been performed and that all the documents released by that division and constituting the BPR

have been correctly and completely filled in. They ensure that any incident has been recorded in the BPR

and reported to Quality Control Department

Each manufacturing run is subject to an output calculation (archive in the BPR) allowing identification of

any abnormal losses.

The BPR are then forwarded to Quality Control Department and submitted to a documented control.

The batch records is in paper version and kept for 1 year after expiry date of batch.

Change Control

A Management of Change procedure (DPPR824005) is in place to ensure that all changes affecting

quality are reviewed and approved prior to implementation.

It is applicable, but not limited to changes in raw materials or packaging and their sources,

material specifications, test methods, manufacturing and analytical equipment, production processes,

and manufacturing or packaging sites. All such changes that potentially impact product

quality require approval of the Quality unit.

Chapter 6: Production

Type of products

The list of the products, which manufactured by DAROU PAKHSH PHARMA. MFG. CO. is provided in the appendix. 2. in a list of human & veterinary & under investigation 6-1-1 Toxic substances

An immunosuppressive drug , Mycophenolate ,is classified as hazardous

6-1-2 Dedicated line

Recently Insulin and Mycophenolate production lines are added as dedicated lines

6-2

process validation

6-2-1 general policy of process validation

process validation newly started and is in progress.

6-2-2 Batch reprocessing

If necessary, batch reprocessing is done according to the defined procedure under deviation and OOS

managment (the procedure is defined by Technical Director, head of QC & QA and Head of Production).

Page 9 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

Material Management &warehousing

6-3-1 Handling of starting materials, packaging materials, intermediate, semi finished and finished

products, including sampling, quarantine, release and storage.

After reception of any raw and packaging material is put in a quarantine zone and labelled accordingly.

Each delivered article is identified by its article number, its supplier batch number and its internal

DAROU PAKHSH PHARMA. MFG. CO. code number.

The delivered batch is sampled (under laminar flow for the raw materials If necessary) according to

procedures and the sampling plan. The samples are transmitted to the Quality Control laboratories and

analysed. The batch is released or rejected, the labels (under test) covered by another label specifying its

new status and among others its expiration date.

A certificate of analysis is edited and signed by the head of Quality Control Department

The Planning division manages the raw materials stock and designates the batches, which will be

delivered to the production division. They will be weighed, mainly in the central weighing facility then

delivered to the manufacturing departments.

The key manufacturing parameters are described in the manufacturing protocols in the form of columns to

be completed, the operators records the controls carried out: these can therefore found in the Batch

Processing Record.

The authorized operator undertakes empty line checks and controls during the course of manufacturing

and packaging, these controls are recorded in the Batch Processing Report.

Intermediate, semi-finished products are sampled according to the current procedures and analysed by the

Quality Control Department.

The laboratories control that the products meet the physico-chemical, and microbiological specifications,

and if applicable biological control and activity specifications, as well as the primary and secondary

packaging specifications.

As the intermediate and semi- finished products constitute the key step of the production process, the

Quality Control department puts them in quarantine until release or rejection. This is also the case for all

finished products.

A certificate of analysis signed by the heads of the Quality Control department and a label (Approved) or

(Rejected) is affixed.

Acceptance or rejection is made on the basis of: § Batch analysis result § Review of the Batch Processing Record § Evaluation of possible non-conformities related to the manufactured batch The storages areas are buildings, which guarantee the security and the quality of the raw materials and products stored (limited access, fire detection and extinguisher system, temperature control). Samples are taken if necessary in sampling rooms under laminar flow. Raw materials are stored in containers, which protect them from dust. The storage area is equipped with air- conditioned rooms for raw materials and products that are sensitive to temperature variations and there is a cold room for the storage for sensitive raw materials.

Page 10 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

The materials in quarantine are stored in a reserved and labeled area.

The status of raw materials, packing materials, intermediate, semi –finished and finished products is

indicated by a system of labeling which indicates clearly whether a material or a product is in quarantine,

released or rejected.

Raw materials are used on a "First In, First Out" (FIFO) basis, as indicated by their expiration date. The

finished products follow in general this principle (except in the case indicated above, when a batch is

reserved for a particular client).

6-3-2 Handing of rejected products and materials

Rejected products are clearly labelled (red labels); they are stored in an area designed for this purpose.

When a sufficient quantity of materials to be destroyed has accumulated, they transported to an

incineration center and destructed according to the guidelines of MOH.

Chapter 7: Quality Control

7-1

Physico-chemical laboratory:

Physico-chemical control and analysis of the quality of the starting materials. intermediate and finished

products.

7-2

Biology laboratory

Microbiological control and analysis of the quality of the raw materials, intermediate and finished

products.

Control of the microbiological quality of the Water ,environment (air, surfaces) and utilities.

Biological control and analysis of raw materials, intermediate, and finished products.

7-3

In – process QC laboratory

In – process control of packaging materials, production procedures, finished products and other differential

important Parameters such as Temperature, Humidity, Pressure, Air Particle counting and … .

7-4

Biotechnology laboratory

Biological assay of insulin , growth hormone , heparin ,enoxoparine and similar drugs.

Chapter 8: Distribution Complaints', PRODUCT DEFECTS & RECALLS

The distribution companies that The DAROU PAKHSH PHARMACEUTICAL MFG. Co. is deal with are:

Darou Pakhsh distribution Company, Momtaz Distribution Company, Exir Company, Poorapakhsh

Company, Darougostar Razi Company, Hejrat Company, Behresan Darou Company, Mahya Darou

Company.

8-1

Batches of products packed are stored; After releasing the batches and when an order arrives, the quantity required is taken from stock. The distribution follow- up system allows a batch to be traced from manufacturing to the customer (date of delivery, quantity, name and address of the customer).

Page 11 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

Complaints and Recalls

There is a written procedure for dealing with quality complaints. This procedure describes in particular the actions to be taken in case of compliant and the responsibilities of the persons that make up the committee for handling complaint, which include among others: § The Technical Director who has responsibility for setting up a centralized documentation of all

information, reports, forms, minutes of meeting, etc.… and for assembling the batch record concerning each complaint, for determining the exact nature of the complaint and for finishing its cause.

§ The head of Marketing Department, whose task is to provide a list of customers who have received the

incriminated batch and establish an inventory of remaining stocks within the company.

§ The head of Quality Control who is responsible for labeling and control of storage of the incriminated

batch, for verifying reference samples, for using or developing control methods in order to complete the inquiry.

Reports are prepared for the different stages in handling the complaint; a final report closes the matter. The reports are submitted to the compliant handling committee; the members of this committee receive a copy of the final report; this system ensures the control of these documents. Each compliant file is retained for at least 2 years after expiring date of the product. The above-mentioned procedure is also used in case of recalls; it describes the process to be followed when compliant - internal company information or a demand from the authorities – justifies a recall. This procedure mentions in particular the sequence of actions to be taken and who is responsible for: § Tracing distribution § Information customers (and how) § Receipt, separate storage and labeling of the returned batch § Inquiring into the cause of the recall § Proposing corrective actions § Coordinating operations related to the recall (establishing the cause of the compliant, contacts with the

authorities, writing of the communications to be issued to the media, report on the progress of return of the batch).

The decision – making scheme describe in this procedure allows to evaluate the risk, and if necessary to

inform the authorities.

The procedure refers to the classification of the quality defects According to MOH of Iran guideline for

setting the mode of recall.

Chapter 9: Self inspection

9-1

Internal audit

The internal audit system is managed by the Responsible pharmasist and /or QA manager and is subject to a Written Instruction (WI). The division involved in manufacturing, storage and controls are regularly audited by the Responsible pharmacist and /or QA manager based on a program. In addition, internal audits may be required in particular cases, for example in the case of a recall, when products are repeatedly rejected, or at the introduction of a new production. The observed weak points are subjected to corrective actions whose implementation and follow – up are the responsibility of the head of the audited division and of the the Responsible pharmasist and /or QA manager, respectively.

Page 12 of 13

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date: 09/05/2016

Rev. No:3

Archiving of the internal audit files (records, reports, follow- up on corrective actions, etc …) is done by

the Responsible pharmacist and /or QA manager.

Page 13 of 13

Appendix 1

Copy of valid manufacturing

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date : 09/05/2016

Rev. No:3

Page 1 of 2

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date : 09/05/2016

Rev. No:3

Page 2 of 2

Appendix 2

List of dosage forms manufactured

including the INN names or common

name of API used

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

Product List

Darou Pakhsh Pharmaceutical Mfg. Co.

Category

Product name

Dosage form

Packaging

Dipifen®

Acetaminophen Codeine

Chew. Tab. 100mg

10 A.S.A Codeine

11 Celexib® ( Celecoxib )

12 Celexib® ( Celecoxib )

Analgesics, Antipyretics

13 Children Cold

Diclen® ( Diclofenac )

15 Diclen® ( Diclofenac Sodium )

Amp. 25mg/ml, 3ml

16 Diclofenac Sodium

17 Diclofenac Sodium

22 Methyl Salicylate

Top. Oint. 30%, 30g

Top. Gel 0.5%, 60g

Amp. 0.5mg/ml, 2ml

Amp. 0.5mg/ml, 5ml

Atracurium besylate

Amp. 10mg/ml , 2.5ml

30 Atracurium besylate

Amp. 10mg/ml , 5ml

31 Fentanyl citrate

Amp. 50mcg/ml, 2ml

Anesthesia adjuncts

32 Fentanyl citrate

Amp. 50mcg/ml, 10ml

Persocaine-E® ( Lidocaine +

Amp. 5mg/ml, 1ml

Page 1 of 10

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

Amp. 5mg/ml, 3ml

37 Dentanest® ( Prilocaine + Felypressin ) Cartridge 1.8ml

Amp. 5mcg/ml, 2ml

Amp. 5mcg/ml, 5ml

Top. Gel 0.1%, 30g

Top. Sol. 1%, 60ml

42 Metronidazole

Top. Gel 0.75%, 30g

Lotion 0.05%, 15ml

Top. Gel 0.025%, 15g

Top. Gel 0.05%, 15g

Antiasthmatic agents

Anti-Cancer agents

Ursodeoxycholic Acid

Inj.6000 IU/0.6 ml

Inj.10000 IU/ ml

Anticoagulant agents

52 Heparin Sodium

Inj. 5000IU/ml, 1ml

53 Heparin Sodium

Inj. 10000IU/ml, 1ml

58 Oxcarbazepine

60 Phenobarbital

65 Amitriptyline

66 Amitriptyline

67 Amitriptyline

68 Tripline® ( Amitriptyline )

Antidepressants Antipsychotics

73 Doxipen® ( Doxepin )

Doxipen® ( Doxepin )

Page 2 of 10

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

76 Nortriptyline

77 Nortriptyline

Amp. 5mg/ml, 1ml

83 Venlafaxine S.R.

Venlafaxine S.R.

Vial (70IU NPH+30IU

Dipisulin-(70/30)® ( Insulin 70/30 )

Regular)/ml, 10ml

88 Dipisulin-N® ( Insulin NPH Human )

Vial 100IU/ml, 10ml

Dipisulin-R® ( Insulin Regular Human )

Vial 100IU/ml, 10ml

Antidiabetic agents

95 Atropine Sulfate

Amp. 0.5mg/ml, 1ml

Anticholinergic Antispasmodic

96 Atropine Sulfate

Amp. 10mg/ml, 2ml

Amp. 1mg/ml, 1ml

Amp. 1mg/ml, 3ml

100 Metoclopramide

Amp. 5mg/ml, 2ml

101 Metoclopramide

Oral Drop 4mg/ml, 15ml

102 Griseofulvin

103 Ketoconazole

104 Ketoconazole

Top. Cream 2%, 30g

Top. Sol. 1%, 10ml

Syr. 5mg/5ml, 60ml

109 Chlorpheniramine

Amp. 10 mg/ml, 1ml

110 Chlorpheniramine

111 Cyproheptadine

112 Diphenhydramine

Elixir 12.5mg/5ml, 60ml

113 Fexofenadine*

Syr. 10mg/5ml, 120ml

Page 3 of 10

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

Syr. 5mg/5ml, 60ml

119 Pediatric Grippe

120 Atorvastatin

121 Atorvastatin

Antihyperlipidemia

122 Atorvastatin

Anti-inflammatory

126 Amikacin Sulfate

Amp. 50mg/ml, 2ml

127 Amikacin Sulfate

Amp. 250mg/ml, 2ml

128 Ciprofloxacin

129 Ciprofloxacin

Amp. 150mg/ml, 2ml

131 Co-trimoxazole

Amp. 10mg/ml, 2ml

Antibacterial agents

Amp. 40mg/ml, 1ml

Amp. 40mg/ml, 2ml

137 Moxifloxacin

141 Ergotamine-C

144 Megrif®* (Sumatriptan+Naproxen)

145 Pyrvinium Pamoate

Susp. 50mg/5ml, 50ml

146 Calcipotriol

Top. Oint. 0.005%, 30g

147 Diphenhydramine compound

148 Expectorant Codeine

Top. Oint. 10%, 5g

152 Aminophylline

Amp. 25mg/ml, 10ml

Amp. 1mg/ml, 1ml

Amp. 0.1mg/ml, 10ml

Syr. 2mg/5ml, 120ml

Page 4 of 10

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

157 Theophylline ER

158 Theophylline ER

Syr. (50+30)mg/5ml,

159 Theophylline G

161 Amlodipine 5/Atorvastatin 20

Cardiovascular agents

168 Dipix® (Clopidogrel)

170 Lozaten® ( Losartan Potassium )

171 Lozaten® ( Losartan Potassium )

172 Lozaten-H® (

Tab. (50+12.5)mg

Losartan+Hydrochlorothiazide )

Oral Sol. 33.3%, 120ml

Cognitive enhancer

178 Barex® ( Barium Sulfate )

179 Gadopentetate dimeglumine

Vial. 469mgI/ml, 20ml

Vial. 150mgI/ml, 20ml

Vial. 150mgI/ml, 50ml

Vial. 270mgI/ml, 20ml

Vial. 270mgI/ml, 50ml

Vial. 320mgI/ml, 50ml

Vial. 300mgI/ml, 20ml

Contrast media agents

Vial. 300mgI/ml, 50ml

Vial. 370mgI/ml, 20ml

Vial. 370mgI/ml, 50ml

189 Iopaque® ( Iohexol )

Amp. 240mgI/ml, 10ml

190 Iopaque® ( Iohexol )

Amp. 240mgI/ml, 20ml

191 Iopaque® ( Iohexol )

Vial. 240mgI/ml, 20ml

192 Iopaque® ( Iohexol )*

Vial. 240mgI/ml, 50ml

193 Iopaque® ( Iohexol )

Amp. 300mgI/ml, 10ml

194 Iopaque® ( Iohexol )

Amp. 300mgI/ml, 20ml

Page 5 of 10

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

195 Iopaque® ( Iohexol )

Vial. 300mgI/ml, 20ml

196 Iopaque® ( Iohexol )*

Vial. 300mgI/ml, 50ml

197 Iopaque® ( Iohexol )

Amp. 350mgI/ml, 20ml

198 Meglumine Compound

199 Meglumine Compound*

200 Meglumine Compound

201 Meglumine Compound*

Dementia symptoms

207 Rivastigmine

208 Rivastigmine

209 Hydrochlorothiazide

Erectile Dysfunction

212 Esomeprazole*

214 Mebeverine E.R.*

Gastrointestinal agents

216 Rabeprazole*

Amp. 25mg/ml, 2ml

219 Dipitropin® (Somatropin)*

Top. Oint. 10%, 30g

Hypopigmenting agents

Immunosuppressant agents

222 Cytocept® (Mycophenolate Mofetil)

223 H.C.G. (Human Chorionic

Gonadotrophin) H.C.G. (Human Chorionic

Infertility therapy adjuncts

225 H.C.G. (Human Chorionic

for Inj. 75IU LH+75IU

H.M.G. (Menotropin)

227 Dextrose 3.33%, NaCl 0.3%

228 Dextrose 3.33%, NaCl 0.3%

Infusions & Irrigation

231 Dextrose 5%, NaCl 0.9%

232 Dextrose 5%, NaCl 0.9%

233 Dextrose 50%

Page 6 of 10

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

236 Sodium Chloride 0.45%

237 Sodium Chloride 0.45%

238 Sodium Chloride 0.9%

239 Sodium Chloride 0.9%

240 Sodium Chloride 0.9%

Sol. For Irrigation 500ml

241 Sodium Chloride 0.9%

Sol. For Irrigation 1Lit.

242 Sterile water for Injection

243 Sterile water for Injection

244 Bromhexine HCl

Elixir 4mg/5ml, 60ml

246 Codeine Phosphate

Amp. 5mg/ml, 1ml

Syr. 25mg/5ml, 250ml

Dispersible Tab. 20mg

Dispersible Tab. 40mg

254 Morphine Sulfate

Amp. 10mg/ml, 1ml

Tincture 1%, 250ml

Nasal Drops, 0.05%,

Nasal Decongestant

Ophthalmic Drops 0.1%,

Ophthalmic Drops 0.2%,

5ml Ophthalmic Drops 2%,

259 Cromolyn Sodium

Ophthalmic Drops 0.1%,

Ophthalmic Drops 2%,

5ml Ophthalmic Drops 0.3%,

Ophthalmic agents

Ophthalmic Drops

0.025%, 5ml Ophthalmic Sol.

Ophthalmic Drops 0.1%,

Ophthalmic Drops 0.1%,

Ophthalmic Drops 0.5%,

Page 7 of 10

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

Ophthalmic Drops 0.5%,

Oral electrolyte

270 Methocarbamol

Amp. 100mg/ml, 10ml

Skeletal muscle relaxants

271 Methocarbamol

272 Pancuronium Bromide

Amp. 2mg/ml, 2ml

273 Phenytoin Sodium

Top. Cream 1%, 30g

Skin healing agents

Top. Oint. 25%, 30g

275 Betamethasone

Amp. 4mg/ml, 1ml

276 Betamethasone

Top. Cream 0.1%, 15g

277 Betamethasone

Top. Lotion 0.1%, 20ml

278 Betamethasone

Top. Oint. 0.1%, 15g

279 Betamethasone L.A.

Top. Cream 0.05%, 15g

Top. Lotion 0.05%, 25ml

Top. Oint. 0.05%, 15g

283 Dexamethasone

Amp. 4mg/ml, 2ml

Steroidal anti-inflammatory

Amp. 40mg/ml , 1ml

285 Dipimedrol®*(Methylprednisolone

vial. 40mg/ml , 1ml

286 Fluocinolone Acetonide

Top. Cream 0.025%, 15g

287 Fluocinolone Acetonide

Top. Oint. 0.025%, 15g

288 Hydrocortisone

Top. Oint. 1%, 15g

289 Hydrocortisone sodium phosphate

Amp. 50mg/ml, 2ml

Hydrocortal® (Hydrocortisone sodium

291 Triamcinolone

Amp. 40mg/ml, 1ml

Sweetening agents

Prostatic hyperplasia therapy

Uterine relaxant

295 Borage Oil (RP Scherer)

Calcium-D Fort® (Calcium

Caplet 500mg+400IU

carbonate+Vit.D3)

Caplet 500mg+200IU

298 Clear Vision Eye Care (RP Scherer)

Vitamins, Minerals & Dietary

299 Cod Liver Oil (RP Scherer)

300 SeaPearl® (Cod liver oil)

301 SeaPearl® (Cod liver oil)

303 Quzyme® (CoQ10)*

304 Energy Plus (RP Scherer)

Page 8 of 10

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

305 Evening Primrose Oil (RP Scherer)

306 Evening Primrose Oil (RP Scherer)

307 Evening Primrose Oil+Vitamin E nat.

Softgel 500mg+6.71mg

Oral Drops 25mg/ml,

308 Feriron® (Ferrous Sulfate)

309 Feriron® (Ferrous Sulfate)

310 Lipex® (Fish oil)

311 Quzyme Fort® (Fish

Oil+CoQ10+Selenium)*

(500+100+75.2)mg

312 Glucosamine Sulfate

313 Arthriflex-C®

Soflet (500+400)mg

314 Glucosamine+chondroitin

Caplet (500+400)mg

316 L-Carnitine/CoQ10

317 Lecithin (RP Scherer)

318 Multivitamin

319 Multivitamin for skin (RP Scherer)

320 Multivitamin M*

321 Multivitamin P*

322 Multivitamin plus Mineral

323 Multivitamin Therapeutic

324 Omega-3 (RP Scherer)

325 Royal Jelly+Ginseng (RP Scherer)

326 Soy Isoflavone (RP Scherer)

Vitamin ACE+Selenium yeast (RP

329 Vitamin B complex

330 Vitamin B complex

Vitamin B1/B6/B12

(100+100+1)mg/3ml, 3ml

Amp. 100mcg/ml, 1ml

Amp. 1000mcg/ml, 1ml

Amp. 50mg/ml, 2ml

Amp. 100mg/ml, 3ml

Amp. 100mg/ml, 5ml

Chew. Tab. 250mg

Amp. 300000IU/ml, 1ml

Page 9 of 10

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date :09/05/2016

Rev. No:3

Chew. Tab. 100IU

343 Evital® (Vitamin E)

344 Evital® (Vitamin E)

345 Vitamin E nat. (RP Scherer)

Softgel 134mg, 200IU

346 Vitamin E nat. (RP Scherer)

Softgel 268mg, 400IU

347 Wheat Germ Oil (RP Scherer)

348 Zinc Gluconate-C-E (RP Scherer)

Softgel (5+60+12)mg

Oral Sol. 1000ml

350 Betamethasone

Amp. 8mg/ml, 10ml

351 Betamethasone*

Vial. 8mg/ml, 50ml

352 Bromhexine HCl

353 Bromhexine HCl

356 Dexamethasone

Amp. 4mg/ml, 10ml

357 Dexamethasone*

Vial. 4mg/ml,50ml

358 Dextrose 3.33%, NaCl 0.3%

359 Dextrose 3.33%, NaCl 0.3%

Veterinary Products

Amp. 50mg/ml, 10ml

Vial. 50mg/ml, 50ml

364 Pregnan® (H.C.G.)

366 Neomycin Sulphate

Top. Oint. 1%, 15g

367 Promethazine

Amp. 25mg/ml, 10ml

368 Promethazine*

Vial. 25mg/ml, 50ml

369 Vit. B Complex

370 Vit. B Complex*

*Will be in the market soon

Page 10 of 10

Appendix 3

Copy of valid GMP Certificate

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date : 09/05/2016

Rev. No:3

Page 1 of 2

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

CODE : DPSMF422

Validation Date : 09/05/2016

Rev. No:3

Page 2 of 2

Appendix 5

Organisational chart

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09/05/2015

: DPSMF422

Validation Date: 09/05/2016

Rev. No:3

Board of Directors

Strategic Planning Manager

Strategic Plans Committee

Auditing Committee

Auditing Manag er

Managing Director

Consultants

Secretarial

Operation VP

Quality Assurance VP

Logistics VP

Finance & Economy VP

Business

Public Relation

Responsible

Scientific Research

Commercial

Security

Development

& International

Pharmacists

& Marketing

Contracts

Affairs Manager

Studies Manager

DAROU PAKHSH

PHARMACEUTICAL MFG. CO.

SITE MASTER FILE

Issued Date: 09.05.2015

CODE: DPSMF422

Validation Date:09.05.2016

Rev. No: 3

Managin g

D irector

Biologic & Biotechnology

Semisolid & Oral Liquid &

Sterile Products Responsible

Solid Responsible

Products Responsible

supplements Responsible

Pharmacist

Pharmacist

Pharmacist

Pharmacist

Secretarial

Secretarial

Secretarial

Secretarial

Responsible

Responsible

Responsible

Responsible

Pharmacist Expert

Pharmacist Expert

Pharmacist Expert

Pharmacist Expert

Source: http://www.dppharma.ir/CorporateSite/media/daroupakhsh-media/pdf/SMF.pdf

Journal of African Studies in Educational Management and Leadership Vol: 7 No:1, August 2016, 61-81 Scholarly, Peer Reviewed Interrogating Social Media Netiquette and Online Safety among University Students from Assorted Disciplines Simon Macharia Kamau, Khadiala Khamasi & Margaret Kamara Kosgey Abstract

La empresa frente a la potestad regulatoria de las administraciones públicas JUNIO DE 2015YO- NÚM. 134 • MA Descubre los límites Director: Luciano Parejo Alfonso -económicos y administrativos- sin romper la cuerda NÚM. 134 • AÑO 14 • MAYO-JUNIO DE 2015