Viagra gibt es mittlerweile nicht nur als Original, sondern auch in Form von Generika. Diese enthalten denselben Wirkstoff Sildenafil. Patienten suchen deshalb nach viagra generika schweiz, um ein günstigeres Präparat zu finden. Unterschiede bestehen oft nur in Verpackung und Preis.

Cronomar.hr

Options and Accessories

Data Logging

Measurement

3 mm - 250 mm (0.110"- 9.995") with

Range in Steel

Adds Data Logging features to the DIVE gauge including DIVELink software

2 mm - 150 mm (0.065"- 6.000") with

for data transfer.

3.5 MHz probe1 mm - 50 mm (0.045"- 4.000") with

Remote display with fixing bracket for Kirby Morgan® helmets with an

0.1 mm (0.005") when calibrated in accordance

accessory mounting point.

with Cygnus Instruments Calibration Procedures

Top Side Repeater

±0.05 mm (±0.002") High <100 mm

The Cygnus Top Side Repeater is a self contained remote display unit that

±0.1 mm (±0.005") Low

can relay the thickness measurement values to the surface. There is also an option to overlay the thickness measurements on a composite video signal

Battery Life

Rechargeable Lithium-Ion Battery pack,

for survey video recording purposes.

2.4" Colour TFT with LED Backlight320 x 240 pixels

Allows remote display of thickness measurements on a computer via two-wire serial data link and also data logging facility on the surface.

105 mm x 110 mm x 35 mm (4.1" x 4.3" x 1.4")

Umbilical Cables - Surface Display

Complete Gauge 905 g (2 lb.)

Cygnus can provide umbilical cables to connect the Cygnus DIVE gauge to

Operating Temp.

-10°C to +50°C (14°F to 122°F)

surface equipment. Custom lengths can be accommodated up to 500 m (1,640 ft).

Depth Rating

IP68 Rated to 300 m (984 ft) continuous

immersion in sea water

Automatic TCG, 1 to 10 MHz Bandwidth10 Bit Digitiser 60 MSPS

Benefits of Cygnus Multiple Echo

Data Storage

32 Mb Flash Memory

Measures remaining metal thickness of corroded and coated structures

(Data Logging Version)

(5000 Measurement Points)

All measurements are error checked using 3 return echoes to give

Data Output

RS-485 Half Duplex to DIVELink

repeatable, reliable results

Accepted by all major classification societies

3 years on DIVE gauge, 6 months on probe

Greatly reduces inspection time and costs

Echo strength indicator to aid measurement.

Kit Contents

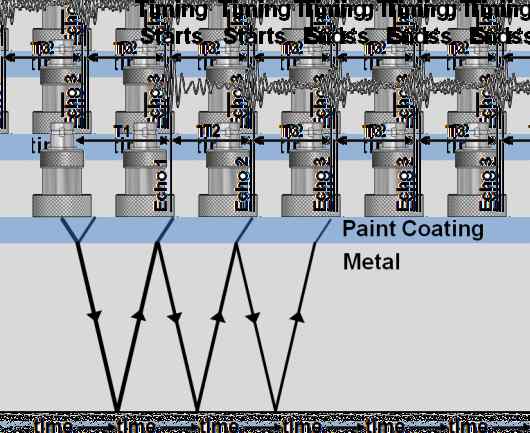

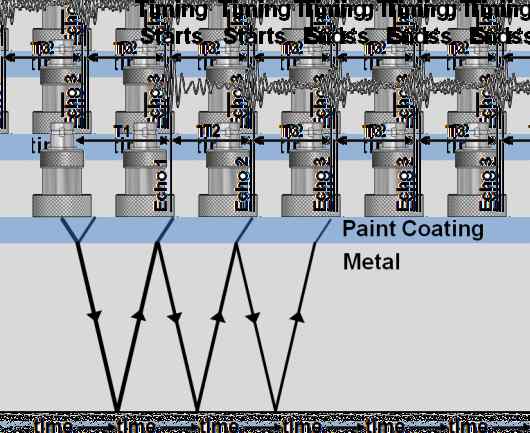

With multiple echo, readings are taken by measuring the time delay between any three consecutive backwall echos. The time of T1 (coating thickness) is

Cygnus DIVE Gauge

ignored. The times of T2 and T3 are equal to the time that it takes to travel through the metal. Only by looking at three echoes can the measurements

2 Rechargeable Batteries

be automatically verified (where T2 = T3).

Ultrasonic Probe (2.25 MHz)

For more products, please visit

Cygnus DIVE

WRIST-MOUNTED UNDERWATER MULTIPLE ECHO

ULTRASONIC DIGITAL THICKNESS GAUGE

Measures metal thickness to determine wastage or corrosion

Cygnus Instruments Ltd • Cygnus House • 30 Prince of Wales Road • Dorchester • Dorset • DT1 1PW • United Kingdom

accurately, quickly and without removing protective coatings

Tel: +44 (0)1305 265533 • Fax: +44 (0)1305 269960 • Email: • Web:

Top Side Repeater (TSR) - Optional

DIVELink Software Option

The latest innovation from the pioneers of the digital multiple echo ultrasonic thickness gauge, the Cygnus DIVE is

The Top Side Repeater is a small display unit that can be

Cygnus DIVELink software provides a top side view of thickness

designed for the professional diver and is accurate, reliable and easy to use. Worn on the diver's forearm, it gives an

used to display the thickness measurements sent from the

measurements, A-Scan graphs and instrument status on a computer.

invaluable free hand while performing thickness surveys.

Cygnus DIVE gauge to the surface.

Data Logging

Made from a tough glass-filled resin, the Cygnus DIVE can withstand the knocks and bumps of the diving environment. A large bright colour TFT screen displays the thickness measurements in big numbers that really stand out - choose the

DIVELink can be used to record thickness measurements as part of a

display colour that suits you.

thickness survey. The operator can choose to log the thickness measurements taken by the diver, or using the A-Scan graph estimate the

TSR Video Overlay Facility

thickness and record this value instead - useful when gauging on heavy

Large, bright colour TFT screen

The Top Side Repeater can also superimpose the thickness measurements

Like all Cygnus products, the Cygnus DIVE has been designed for easy operation. There are no gates to set up, no gain to

on to a composite PAL or NTSC video signal to display it on a monitor screen

adjust - just turn on and go. There are two buttons for quick and easy menu navigation using one hand, from here you can

Instrument Status and Control

and/or the video recording of the survey. This provides a thickness

access all the functions of the gauge guided by intuitive, clear menus.

measurement that can be linked to a position or place in the video recording.

DIVELink allows an operator to see the battery status of the Cygnus DIVE.

The material velocity, unit and Deep Coat settings can also be changed from

Kit includes data and video cables.

the surface.

Power is supplied by a replaceable, rechargeable Lithium-Ion battery pack that gives up to 10 hours continuous operation.

The Cygnus DIVE uses the trusted Multiple Echo Technique first developed by Cygnus 30 years ago. With minimal

surface preparation, the Cygnus DIVE will measure metal thickness through paint and other coatings. The Multiple Echo Intuitive, clear menus

Monitor &

Technique ensures only genuine, verified thickness measurements are displayed.

The ultrasonic probe is connected to the Cygnus DIVE by a coiled double jacket cable and rugged locking connector. The coiled cable will extend up to 1 metre (3 ft) in length for reaching around structures. A replaceable membrane ensures long

Camera Feed

Deep Coat

The Deep Coat function allows the Cygnus DIVE to measure metal thickness through coatings up to 20 mm (3/4") thick.

Coiled double jacket cable

Often divers face taking thickness measurement surveys in black or limited visibility water so Cygnus developed HelmetView™.

A small remote display is mounted just in front of the lens on the diver's helmet using the accessory screw, a short cable then plugs in to the Cygnus DIVE's top side

Data Logging Option

To assist with the verification of thickness measurements, and

The Cygnus DIVE can store up to 5000 thickness

Thickness measurement values are then clearly visible to the diver - even if they can't see any further.

to help locate suitable ultrasound reflectors on badly corroded

measurement points in internal flash memory.

metal, the Cygnus DIVE can display an A-Scan graph of the

Thickness measurements are clearly displayed on an OLED display and its brightness can be adjusted from the menu on the Cygnus DIVE gauge.

ultrasound received.

When a multiple echo thickness measurement is detected the

Thickness measurements are recorded using an

ultrasound peaks used are clearly marked to aid measurement

Auto-Log feature that saves each stable

measurement - this means no ‘log' button for the diver to press.

Surface View

A-Scan Graph

The A-Scan graph can be viewed at the surface on a computer using Cygnus DIVELink software and the A-Scan graph is also

Along with the thickness measurement, a copy of the A-Scan graph is also saved.

recorded when data logging thickness measurement points.

Data logged measurements are easily transferred from the Cygnus DIVE to a computer using the DIVELink software supplied. From there a paper report can be produced or the thickness measurements can be exported to a spreadsheet.

Measurements can be split into groups by simply starting a new group via the DIVE's easy to use menu.

Divers View

Top Side Repeater (TSR) - Optional

DIVELink Software Option

The latest innovation from the pioneers of the digital multiple echo ultrasonic thickness gauge, the Cygnus DIVE is

The Top Side Repeater is a small display unit that can be

Cygnus DIVELink software provides a top side view of thickness

designed for the professional diver and is accurate, reliable and easy to use. Worn on the diver's forearm, it gives an

used to display the thickness measurements sent from the

measurements, A-Scan graphs and instrument status on a computer.

invaluable free hand while performing thickness surveys.

Cygnus DIVE gauge to the surface.

Data Logging

Made from a tough glass-filled resin, the Cygnus DIVE can withstand the knocks and bumps of the diving environment. A large bright colour TFT screen displays the thickness measurements in big numbers that really stand out - choose the

DIVELink can be used to record thickness measurements as part of a

display colour that suits you.

thickness survey. The operator can choose to log the thickness measurements taken by the diver, or using the A-Scan graph estimate the

TSR Video Overlay Facility

thickness and record this value instead - useful when gauging on heavy

Large, bright colour TFT screen

The Top Side Repeater can also superimpose the thickness measurements

Like all Cygnus products, the Cygnus DIVE has been designed for easy operation. There are no gates to set up, no gain to

on to a composite PAL or NTSC video signal to display it on a monitor screen

adjust - just turn on and go. There are two buttons for quick and easy menu navigation using one hand, from here you can

Instrument Status and Control

and/or the video recording of the survey. This provides a thickness

access all the functions of the gauge guided by intuitive, clear menus.

measurement that can be linked to a position or place in the video recording.

DIVELink allows an operator to see the battery status of the Cygnus DIVE.

The material velocity, unit and Deep Coat settings can also be changed from

Kit includes data and video cables.

the surface.

Power is supplied by a replaceable, rechargeable Lithium-Ion battery pack that gives up to 10 hours continuous operation.

The Cygnus DIVE uses the trusted Multiple Echo Technique first developed by Cygnus 30 years ago. With minimal

surface preparation, the Cygnus DIVE will measure metal thickness through paint and other coatings. The Multiple Echo Intuitive, clear menus

Monitor &

Technique ensures only genuine, verified thickness measurements are displayed.

The ultrasonic probe is connected to the Cygnus DIVE by a coiled double jacket cable and rugged locking connector. The coiled cable will extend up to 1 metre (3 ft) in length for reaching around structures. A replaceable membrane ensures long

Camera Feed

Deep Coat

The Deep Coat function allows the Cygnus DIVE to measure metal thickness through coatings up to 20 mm (3/4") thick.

Coiled double jacket cable

Often divers face taking thickness measurement surveys in black or limited visibility water so Cygnus developed HelmetView™.

A small remote display is mounted just in front of the lens on the diver's helmet using the accessory screw, a short cable then plugs in to the Cygnus DIVE's top side

Data Logging Option

To assist with the verification of thickness measurements, and

The Cygnus DIVE can store up to 5000 thickness

Thickness measurement values are then clearly visible to the diver - even if they can't see any further.

to help locate suitable ultrasound reflectors on badly corroded

measurement points in internal flash memory.

metal, the Cygnus DIVE can display an A-Scan graph of the

Thickness measurements are clearly displayed on an OLED display and its brightness can be adjusted from the menu on the Cygnus DIVE gauge.

ultrasound received.

When a multiple echo thickness measurement is detected the

Thickness measurements are recorded using an

ultrasound peaks used are clearly marked to aid measurement

Auto-Log feature that saves each stable

measurement - this means no ‘log' button for the diver to press.

Surface View

A-Scan Graph

The A-Scan graph can be viewed at the surface on a computer using Cygnus DIVELink software and the A-Scan graph is also

Along with the thickness measurement, a copy of the A-Scan graph is also saved.

recorded when data logging thickness measurement points.

Data logged measurements are easily transferred from the Cygnus DIVE to a computer using the DIVELink software supplied. From there a paper report can be produced or the thickness measurements can be exported to a spreadsheet.

Measurements can be split into groups by simply starting a new group via the DIVE's easy to use menu.

Divers View

Options and Accessories

Data Logging

Measurement

3 mm - 250 mm (0.110"- 9.995") with

Range in Steel

Adds Data Logging features to the DIVE gauge including DIVELink software

2 mm - 150 mm (0.065"- 6.000") with

for data transfer.

3.5 MHz probe1 mm - 50 mm (0.045"- 4.000") with

Remote display with fixing bracket for Kirby Morgan® helmets with an

0.1 mm (0.005") when calibrated in accordance

accessory mounting point.

with Cygnus Instruments Calibration Procedures

Top Side Repeater

±0.05 mm (±0.002") High <100 mm

The Cygnus Top Side Repeater is a self contained remote display unit that

±0.1 mm (±0.005") Low

can relay the thickness measurement values to the surface. There is also an option to overlay the thickness measurements on a composite video signal

Battery Life

Rechargeable Lithium-Ion Battery pack,

for survey video recording purposes.

2.4" Colour TFT with LED Backlight320 x 240 pixels

Allows remote display of thickness measurements on a computer via two-wire serial data link and also data logging facility on the surface.

105 mm x 110 mm x 35 mm (4.1" x 4.3" x 1.4")

Umbilical Cables - Surface Display

Complete Gauge 905 g (2 lb.)

Cygnus can provide umbilical cables to connect the Cygnus DIVE gauge to

Operating Temp.

-10°C to +50°C (14°F to 122°F)

surface equipment. Custom lengths can be accommodated up to 500 m (1,640 ft).

Depth Rating

IP68 Rated to 300 m (984 ft) continuous

immersion in sea water

Automatic TCG, 1 to 10 MHz Bandwidth10 Bit Digitiser 60 MSPS

Benefits of Cygnus Multiple Echo

Data Storage

32 Mb Flash Memory

Measures remaining metal thickness of corroded and coated structures

(Data Logging Version)

(5000 Measurement Points)

All measurements are error checked using 3 return echoes to give

Data Output

RS-485 Half Duplex to DIVELink

repeatable, reliable results

Accepted by all major classification societies

3 years on DIVE gauge, 6 months on probe

Greatly reduces inspection time and costs

Echo strength indicator to aid measurement.

Kit Contents

With multiple echo, readings are taken by measuring the time delay between any three consecutive backwall echos. The time of T1 (coating thickness) is

Cygnus DIVE Gauge

ignored. The times of T2 and T3 are equal to the time that it takes to travel through the metal. Only by looking at three echoes can the measurements

2 Rechargeable Batteries

be automatically verified (where T2 = T3).

Ultrasonic Probe (2.25 MHz)

For more products, please visit

Cygnus DIVE

WRIST-MOUNTED UNDERWATER MULTIPLE ECHO

ULTRASONIC DIGITAL THICKNESS GAUGE

Measures metal thickness to determine wastage or corrosion

Cygnus Instruments Ltd • Cygnus House • 30 Prince of Wales Road • Dorchester • Dorset • DT1 1PW • United Kingdom

accurately, quickly and without removing protective coatings

Tel: +44 (0)1305 265533 • Fax: +44 (0)1305 269960 • Email: • Web:

Source: http://cronomar.hr/uploads/documents/equipment/podvodni_ultrazvucni_mjerac_debljine_stijenke.pdf

Topical Immunomodulator Department of Dermatology Seoul National University College of Medicine Topical Calcineurin Inhibitors Tacrolimus Protopic: 822 Da 0.1%, 0.03% oint epi-chloro double bond double bond Calcipotriol: 313 Tretinoin: 300 Da) Clinical Efficacy of TCIs: already proven tacrolimus(Protopic), pimecrolimus(Elidel)

Curriculum Vitae Priv. Doz. Dr. Siegfried Wieshammer Geburtsjahr: 1954 Tätigkeit: Chefarzt der Kardiologie, Pneumologie, Angiologie und Intensivmedizin, Ärztlicher Leiter des Pneumologisch-Thoraxchirurgischen Zentrums (PTZ) am Ortenau Klinikum Offenburg-Gengenbach Gebiet, Teilgebiet und Schwerpunktkompetenzen: Facharzt für Innere Medizin, Kardiologie, Pneumologie, Spezielle Internistische Intensivmedizin Studium: 1974-1980 Studium der Humanmedizin an der Ludwig-Maximilians-Universität